Campbell Hausfeld NB0030 Operations Instructions Page 4

- Page / 8

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

prise, l’éjection accidentelle d’at-

taches peut se produire lorsque l’on

démonte la section avant de l’ap-

pareil.

3. Oter les (3) vis à tête cylindrique de

l’avant de l’ap-

pareil et dépos-

er la plaque de

garniture, la

plaque d’e-

spacement et le mécanisme de

déclenchement par contact (WCE)

afin que le clou bloqué soit visible.

4.

Remettre en place tous les éléments

en inversant les étapes décrites en 3.

5. S’assurer que le mouvement de la

gâchette et du

mécanisme de

déclenchement par

contact (WCE) puisse

s’effectuer vers le

haut ou vers le bas sans difficulté.

Support technique

Pour tout renseignement sur le fonc-

tionnement ou la réparation de cette

cloueuse, veuillez appeler notre

numéro d’assistance telephonique sans

frais: 1-866-220-2097.

Attaches et Pièces

de Rechange

N’utiliser que des clous Nº 18 ou un

équivalent. La performance de l’outil,

sa sécurité et sa durabilité pourraient

être réduites si l’on utilise de mauvais-

es attaches. Lors d’une commande de

pièces de rechange ou de clous, préciser

le numéro de pièce.

Réparation de la cloueuse

Seul le personnel dûment qualifié

devrait réparer l'outil en utilisant des

pièces de rechange et des accessoires

qui fonctionnent de manière équiva-

lente.

Méthode d’assemblage pour

les joints d’étanchéité

Les pièces internes doivent être net-

toyées et graissées pendant la répara-

tion d’une cloueuse. Utiliser de la

graisse sur tous les joints toriques.

Chaque joint torique doit être enrobé

de graisse avant l’assemblage.

!

AVERTISSEMENT

5-Fr

Instructions d’utilisation

Operating The Tool

(Continued)

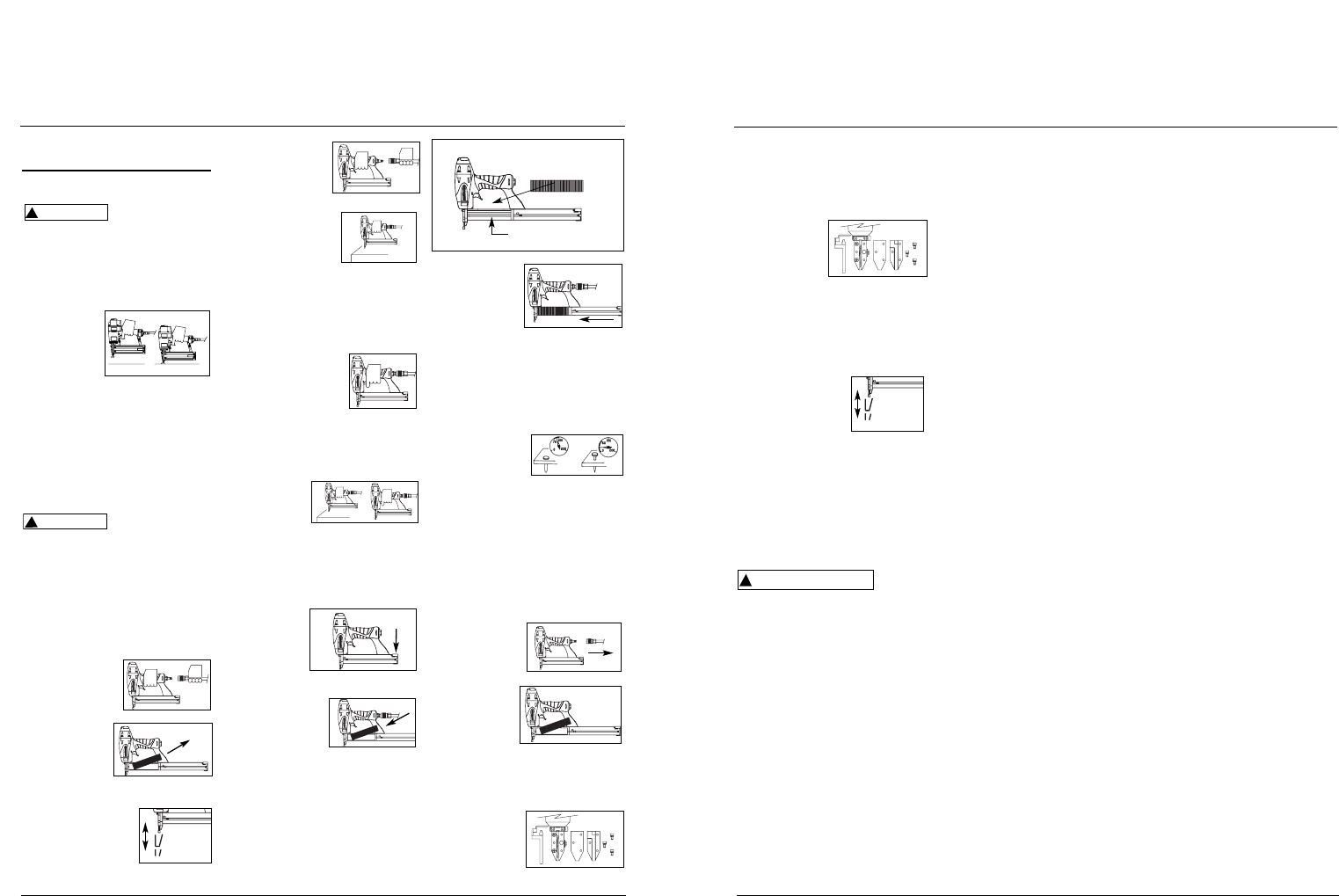

OPERATIONAL MODE

Always know the

operational mode

of the nailer before using. Failure to

know the operational mode could

result in death or serious personal

injury.

SINGLE SEQUENTIAL MODE

This mode requires the trigger to be

pulled each time

a nail is driven.

The nailer can

be actuated by

depressing the

WCE against the work surface followed

by pulling the trigger.

The trigger must be released to reset

the tool before another nail can be dri-

ven.

CHECKING THE WORK CONTACT

ELEMENT (WCE)

Check the opera-

tion of the Work

Contact Element (WCE) trip mechanism

before each use. The WCE must move

freely without binding through its

entire travel distance. The WCE spring

must return the WCE to its fully

extended position after being

depressed. Do not operate the tool if

the WCE trip mechanism is not operat-

ing properly. Personal injury may

occur.

1. Disconnect the

air supply from

the tool.

2. Remove all fas-

teners from the

magazine. (See

"Loading/

Unloading the

Tool" section.)

3. Make sure the trig-

ger and Work

Contact Element

(WCE) move freely

up and down with-

out sticking or binding.

!

CAUTION

!

WARNING

4. Push the mag-

azine cover

forward until

latch button

pops up.

5. Always unload all fasteners before

removing tool from service.

Unloading is the reverse of loading,

except always disconnect the air

supply before unloading.

ADJUSTING THE FASTENER PENE-

TRATION

1. Regulate the air

pressure to 60

PSI at the tool.

2. Connect the air supply and test for

penetration by driving fasteners

into a sample piece of wood. If the

fasteners do not achieve the desired

penetration, adjust the air pressure

to a higher setting until the desired

penetration is achieved. Do not

exceed 100 psi at the tool or dura-

bility of the tool will be reduced.

CLEARING A JAM FROM THE TOOL

1. Disconnect the

air supply from

the tool.

2. Remove all

fasteners

from the

magazine (see

"Loading/

Unloading The Tool"). Failure to do

so will cause the fasteners to eject

from the front of the tool when the

nose assembly is removed.

3. Remove (3) cap

screws from

the nose of the

tool. Remove

nose plate,

spacer and Work Contact Element

4. Reconnect air sup-

ply to the tool.

5. Depress the Work

Contact Element

(WCE) against the

work surface with-

out pulling the

trigger. The tool MUST NOT

OPERATE. Do not use the tool if it

operates without pulling the trig-

ger. Personal injury may result.

6.

Remove tool from the work surface.

The Work Contact

Element (WCE) must

return to its original

down position. Pull

the trigger. The tool

MUST NOT OPERATE. Do not use

the tool if it operates. Personal injury

may result.

7. Depress the Work Contact Element

(WCE)

against the

work surface.

Pull the trig-

ger. The tool MUST OPERATE.

LOADING/UNLOADING THE TOOL

1. Always connect the tool to the air

supply before loading fasteners.

2. Push down

on the latch

button. Pull

back on the

magazine

cover.

3a. For nails, insert a stick of nails or

equivalent (see

"Fasteners"

section) into the

magazine. Make

sure the pointed ends of the fasten-

ers are resting on the bottom ledge

of the magazine when loading.

Make sure the nails are not dirty or

damaged.

3b. For staples, load a clip of staples

with the crowns straddling the mag-

azine rail.

Operating Instructions

4

movement

Latch

Button

Magazine rail

Mouvement

(12 pages)

(12 pages)

Comments to this Manuals