Campbell Hausfeld WL6500 Series Specifications Page 2

- Page / 24

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

Oilless Compressors

General Safety

Information (Continued)

3. Only persons well acquainted with

these rules of safe operation should

be allowed to use the compressor.

4. Keep visitors away and NEVER allow

children in the work area.

5. Wear safety glasses and use hearing

protection when operating the

pump or unit.

6. Do not stand on or use the pump or

unit as a handhold.

7. Before each use, inspect compressed

air system and electrical components

for signs of damage, deterioration,

weakness or leakage. Repair or

replace defective items before using.

8. Check all fasteners at frequent

intervals for proper tightness.

_WARNINGI

Motors. efectrkal

equipment and controls

can cause electrical arcs

that will 19nite • flammable gas or

vapor. NeVer operate or repair In or

near a flammable gss or vapor. Never

store or spray flammable liquids or

gases In the vtcin/ty of b'le compressor.

Compressor part: may be

hot even ff the unit is

stoppnd.

g. Keep fingers away from a running

compressor, fast moving and hot

parts will cause injury and/or burns.

t0. If the equipment should start to

abnormally vibrate, STOP the

engine/motor and check

immediately for the cause. Vibration

is generally a warning of trouble.

11.To reduce fire hazard, keep

engine/motor exterior free of oil

solvent, or excessive grease.

Ng_r rgm_o_ or

a_npt to a_f._

_ p•int _,d ether a_let_s.

Never ammPt to i_pair

or modify • 1onkl

wvnv.chpower.€om

Welding, drilling or any other.

modiflcltinn will weaken the tank

resulting In damage from nlpture or

expinsinn. Always _plece worn or

dam:gad tenk_

I NOTICE I _.inl_.ld_..

tank dally.

12. Tanks rust from moisture build-up,

which weakens the tank. Make sure

to drain tank regularly and inspect

periodically for unsafe conditions

such as rust formation and corrosion.

t3. Fast moving air will stir up dust and

debris which may be harmful. Release

air slowly when draining moisture or

depressudzil_cJ the compressor system.

SPRAYING PRECAUTIONS

IAWARNINGI

Do not spray flammable

meterfait in vicinity of

open flame or near

ignition sources including the

€ompre_or unlL

14. Do not smoke when spraying paint,

insecticides, or other flammable

substances.

15. Use a face mask/

resplretor when

spraying and spray in

a well ventilated area

to prevent health and

fire hazards.

16. Do not direct paint or other sprayed

material at the compressor. Locate

compressor as far away from the

spraying area as possible to

minimize overspray accumulation

on the compressor.

17.When spraying or cleaning with

solvents or toxic chemicals, follow

the instructions provided by the

chemical manufacturer.

Assembly

HANDLE/_SI:MBLY

Compressor handle has a notch (or

detent) at top of handle. This notch

provides a handy place to hang a spray

gun, sandblast gun. or other tool

equipped with a hook.

t. If a handle grip was incioded with

the unit, coat the inside of grip with

a thin film of soapy water. Push grip

onto handle.

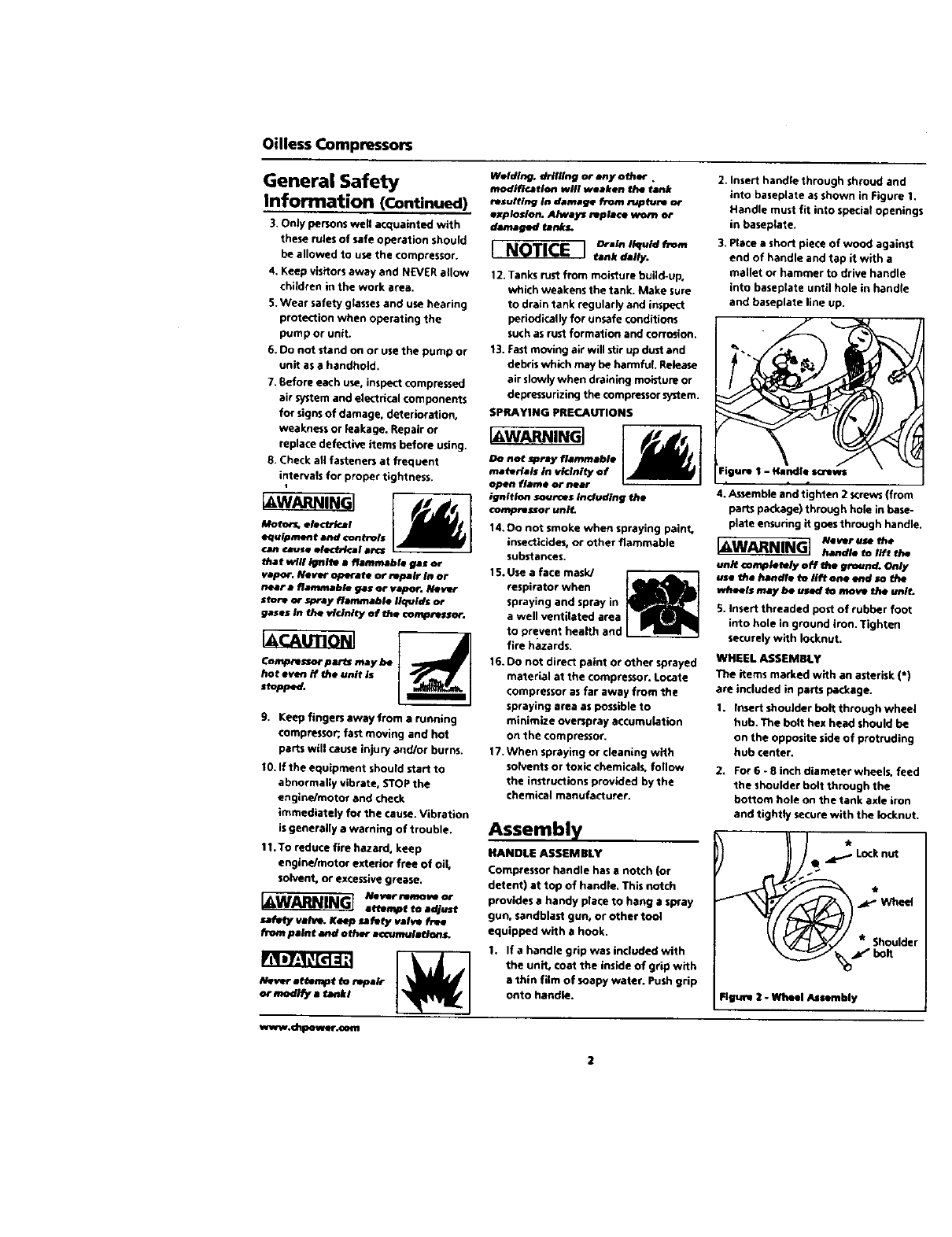

2. Insert handle through shroud and

into baseplate as shown in Figure 1,

Handle must fit into special openings

in baseplate.

3. Place a short piece of wood against

end of handle and tap it with a

mallet or hammer to drive handle

into haseplate until hole in handle

and baseplate line Up.

4. Assemble and tighten 2 screws (from

parts package) through hole in base-

plate ensudng h goeslhrough handle.

Ne vIFr USe t_le

handle to lift the

unit completely off the ground. Only

use the hand/e to lift one end so the

wheets may be usecl to movt the unlt

5. Insert threaded post of rubber foot

into hole in ground iron. Tighten

securely with Iocknut.

WHEEL ASSEMBLY

The items marked with an asterisk (*)

are included in parts package.

1. Insert shoulder bolt through wheel

hub. The bolt hex head should be

on the opposite side of protruding

hub <:enter.

2. For 6 - 8 inch diameter wheels, feed

the shoulder bolt through the

bottom hole on the tank axle iron

and tightly secure with the iocknut.

)Q _ Lock nut

a u,der

Figure 2 -wheel Assembly

- Oilless Air 1

- IRONFORCF__ Compressors 1

- General Safety 2

- Information (Continued) 2

- IAWARNINGI 2

- Assembly 2

- Assembly (Con't) 3

- Installation 3

- Operation 4

- Maintenance 5

- I_CAUTZONI 6

- WL6500 Series 7

- Limited Warranty 8

- Compresseurs 9

- I AWERTISSEMEm] 10

- IAATrENTIONI 11

- LAAVamSSEaE 12

- Entretien 13

- Cornpresseurs Sans Huile 14

- Guide de D_pannage 14

- 3.Remp_'erour_oa_r 14

- Sdrie WL6500 15

- Guide de D_pannage (Suite) 15

- Garantle I.imlt_e 16

- Compresores 17

- Sin Aceite 17

- ONJl--/I 18

- IAPRECAUCIONI 19

- I ADVERTENOAI 20

- Funcionamiento 21

- IAADVERTENCIAI 21

- CompresoresSinAceite 22

- GuiadeDiagn6sticodeAverlas 22

- Serie WL6500 23

- Garantla Limitada 24

(24 pages)

(24 pages) (16 pages)

(16 pages)

Comments to this Manuals